Porsche 911 donor car’s structure has been thoroughly reinforced with a labor intensive stitch welding procedure and the addition of a lightweight integral backbone structure that helps further improve the chassis torsional rigidity. A developmental carbon-fiber second skin further aids this rigidity. The benefits of such measures to ride and handling given the improvements in unibody’s resistance to twisting are vast, as the suspension is converted from torsion bars to the Macpherson strut and Carrera SC rear trailing arm with coilover set-up seen on vintage racing 911′s. Moton dampers with remote oil reservoirs and Eibach springs are used at all four corners and offer multiple settings for ride and handling that the steel shell can now fully exploit. The Singer 911 will also benefit from extensive use of Smart Racing suspension products, such as multi-adjustable anti-roll bars, suspension bushing that help maintain correct geometry.

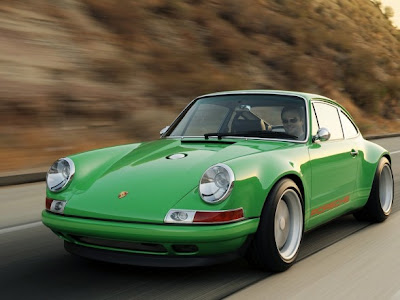

The racing 911′s were famous for their braking ability and making up distance on the competition in the corners. The Singer 911 is equipped with competition-proven Brembo calipers (4-pot) and rotors that are derived from the 917 and 930 models. The brakes will be peeking out from behind period-evoking Zuffenhaus, lightweight, five-spoke, three-piece forged aluminum wheels. The 17 x 9-inch front wheels are wrapped in sticky, modern Michelin Pilot Sport Cup tires measuring 225/45/17 and the rear 17 x 11-inch wheel wears 275/40/17 rubber.

The Singer 911 utilizes the most evolved air/oil cooled 911 engine from the 993. However, the goal with the stock 3.6-liter engine was to develop it into the most modern rendering of the air/ oil cooled engine concept. With the help of U.K.-based, Ninemeister, masterminded by engineer, Colin Belton, and constructed in San Francisco by famed engine builder Jerry Woods Enterprises, the stock 3.6-liter engine is rebuilt to displace 3.82 liters. The engine has been recreated with premium components successfully developed and proven through Ninemeister’s racing exploits. The Singer 911′s engine achieves its displacement with Ninemeister 103mm pistons and cylinders, the 76.4mm crankshaft of the 997 GT3, and the 132mm lightweight titanium connecting rods. The large bore, short stroke combination can spin to 8000 rpm, but offers a broad, flexible torque curve. The key to the power are the highly developed Ninemeister billet aluminum heads that allows this 12-valve engine to compete with the power of water-cooled 24-valve engines found in the latest version of the GT3. A completely re-engineered component the billet aluminum Ninemeister heads are stronger, more resistant to extreme heat, and feature the latest thinking in port design to vastly improve the breathing and output of these motors.

No comments:

Post a Comment